WASH TANK

By Dennis O' Connor

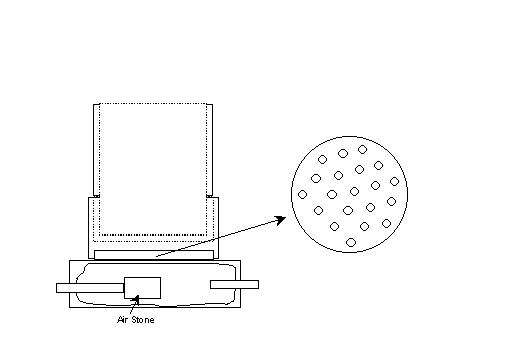

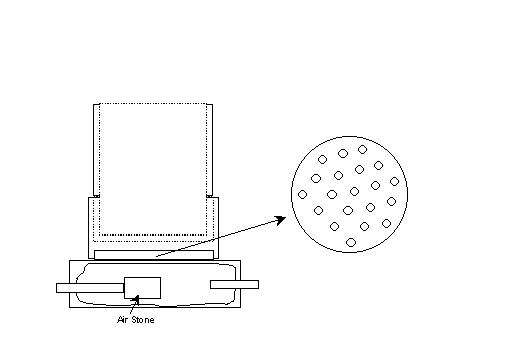

As promised here is my sketch of the print/film washing tank I designed. It was intended to reduce the space required on the sink drainer, and reduce the volume of water used by introducing turbulance with the aid of a fish tank areator.

The components used are obtained from any DIY supplier and consist of:

The Body of the unit. A length of drainage pipe. These are approximately 100mm or 4 inches in dia. This means that a 10 inch print when be curved will fit internally.

The base consists of a pipe connector bonded on to a sheet of rigid plastic.

The connector has a rubber seal at one end, this is where the tank body pushed into place.

Before bonding the base. Drill two holes and fit a `water inlet' supply pipe, and an air inlet pipe (to which is attached the `air stone').

Above this fits a circular disc of rigid plastic which has a number of holes drilled in it.

The developed/fixed print is curved along its 10 inch side and held inside any suitable tube shaped holder. I made some stainless steel coils.

The holder and print are then dropped into the tank where the agitated water can remove any fixative for the required amount of time.

I have made a number of different length bodies, which I combine with different designs of print holding coil. This allows me the option of washing prints larger than 8 x 10.

Films for washing can be dropped into the tank without the need for removing them from their holder.

I hope you find this idea useful. I would be interested to hear if any CRC members have made and used my `Zone Gauge' which

you kindly published in a previous issue.

Heres a thought. If any member has a problem they need to solve. Why not include it in the CRC magazine and see what solutions other members can supply.