Maintenance log for Winter/Spring/Summer 2012/2013

August 22, 2013

1) Completed rewinding of the English Post Horn rank so it doesn't

chatter with the tremulants on.

2) Two new ranks are installed in the Solo chamber, a Smith/Gottfried Open

Diapason and a Smith/Gottfried Vox Humana .

3) Tremulant on the Oboe Horn is corrected by installing metal separators

between the Oboe Horn and Post Horn chests.

4) Stated wiring of the traps and percussions in the Solo chamber.

June, 2013

1) Frans Bosman repaired the broken miters on the 16' Violone pipes

CCC and CCC#, and the CC3 of the Violin that broke off at the toe. The two 16'

Violone pipes hadn't spoken in years.

2) Re-installed the top octave chest for the Solo Tibia and replaced the

pipes with Wurlitzer Tibia pipes.

3) Replaced the 2' octave of the Main Tibia with brand new Wicks pipes.

September 7, 2012

1) Mike Bryant completed required changes to the Uniflex ODF to accommodate

the changes and additions to the Solo chamber .

2) The new Quintadena and Oboe Horn ranks are quite useful, the Oboe Horn is a

little loud.

3) Tremulant on the Oboe Horn is much less deep than the other ranks on the same

regulator. Maybe due to the leather only separators absorbing the energy of the

tremulant.

4) Many slow notes on the English Post horn, more primary valve work needs to be

done.

September 5, 2012

1) Completed wiring of the new English Post Horn chest to the

spreader junction.

2) Inserted driver chips into output boards for the new rank..

August 27, 2012

1) Tuned Oboe Horn rank. The two replacement Wurlitzer pipes don't

want to tune.

2) Finished general clean up of Solo chamber.

3) Dropped C side Post Horn Bottom board and replaced four primary

valves. No leaks, two primaries still not responding correctly.

4) Cleared dead notes from C# side Post Horn. Replaced many Kimball magnet

armatures with the thicker OSI replacements, which seem to work better on the

higher pressure rank.

August 23, 2012

1) Installed ground buss bars on new two rank chest and connected

grounds.

2) Started general clean up of Solo chamber.

3) Dropped C# side Oboe Horn Bottom board and replaced lowest two primary

valves. No longer leaks.

August 21, 2012

1) Installed the OSI/Wurlitzer tremulant. Made no difference in the

performance of the tremulant. Checked the regulator valves and repaired some

large holes in the pallet leather.

August 20, 2012

1) Installed the Vox Humana and Kinura pipes, rough tuned the Vox

Humana and checked tuning on the Quintedena.

2) Shortened the Solo 1 tremulant wind line but it made no difference in the

performance. Acquired an OSI copy of a large size Wurlitzer tremulant, will

install tomorrow.

August 17, 2012

1) The

Quintedena pipes are now installed voiced, regulated and tuned by Franz B. Many

stopper caps were re-packed. Cut-up raised on most pipes.

2) Fixed two dead notes on the Gamba rank by adjusting the primary valves.

3) Fixed numerous hissing wind leaks. The chamber is noticeably quieter

4) The Solo 1 tremulant unit may have to be relocated, doesn't want to adjust

properly. Easy fix to shorten wind line.

August 13, 2012

1) Lou Paff completed bushing the rack board with felt for the

Quintedena pipes.

2) Eight Quintedena pipes sent out for repair. They had dents and small cracks on the

cap solder joints which kept them from speaking properly..

3) English Post Horn winding is complete and set to 17" w/p. Installed C

side bottom board.

4) Started clearing leaks, dead notes and ciphers from Post Horn chest. Will

take some work to get it all playing.

August 3, 2012

1) Wiring complete on the Oboe horn chest. All notes play. CC# and

DD# have primary valves not seating correctly, will require removing bottom

board to fix.

2) Marc Gerlach completed enlarging the rack board holes for the Quintadena. Some

pipes required leather donuts around the toe to prevent them from protruding too

far into the chest toe hole. Many stoppers need to be repacked.

3) Layed out winding for the Post winker. One Post Horn bottom board was

installed.

August 2, 2012

1) Started wiring and re-gasketing the bottom boards for the English

Post Horn chest. Some primary valves require adjustment also.

July 27, 2012

1) Installation progresses on the two rank Kimball wind chest for the

new Morton Oboe Horn and existing Gottfried English Post Horn. Both ranks are

racked up.

2) The new Marr & Colton Quintadena rank is being installed in place of the

existing Post Horn rank. This requires enlarging some rack board holes and

bushing others with adhesive felt. It will be winded with the Solo wind group,

which includes the Saxophone, Gamba, Gamba Celeste, Kinura and Quintadena.

July 23, 2012

1) Removed old Kimball single rank wind chest and installed the new

two rank wind chest. The Marr & Colton Horn rank will be replaced by a

Morton Oboe Horn.

2) Modified wind line to the Oboe Horn chest. Pressure tested Oboe horn

chest.

3) Marc Gerlach started racking up the Marr & Colton Quintadena.

July 13, 2012

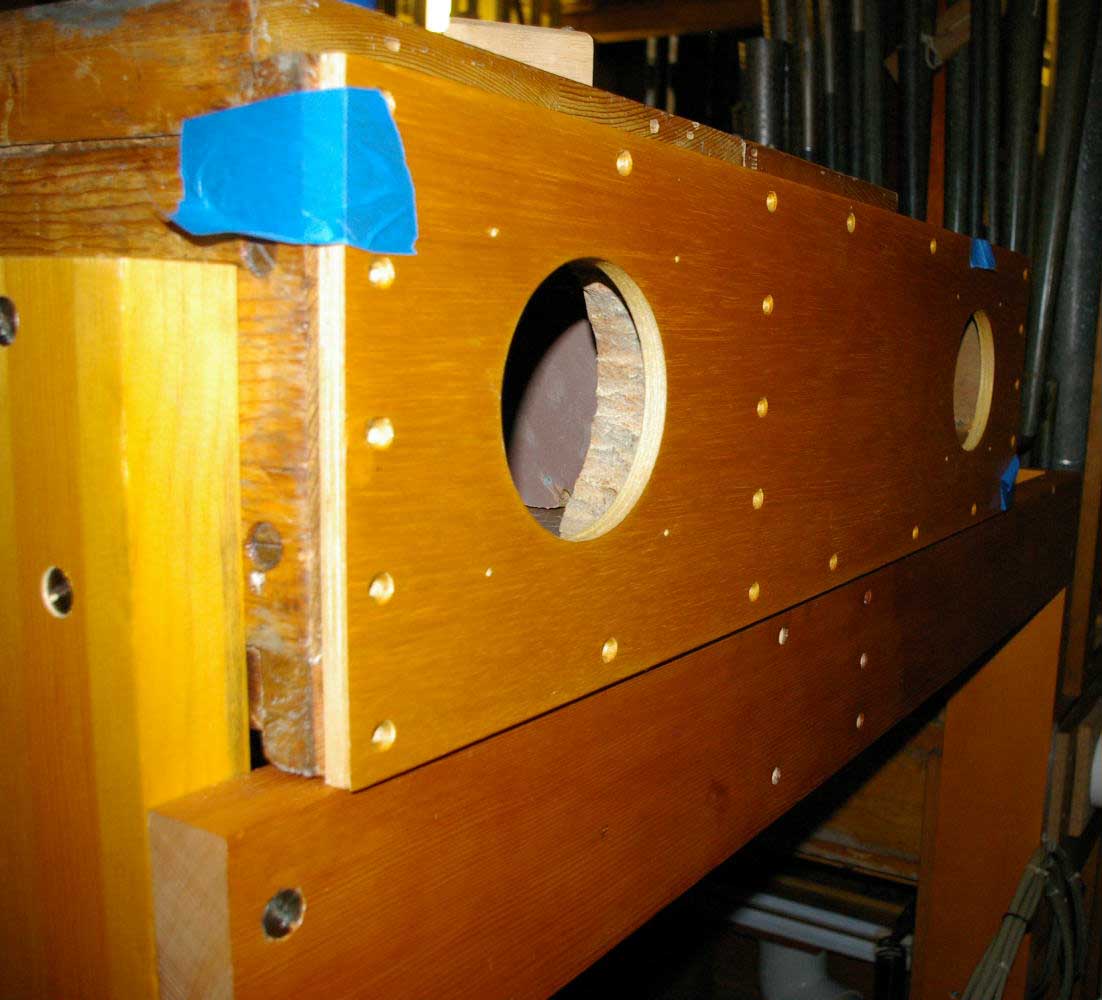

1) Finished making new rack boards for the modified two rank Kimball

wind chest.

2) New end pieces finished to convert the Kimball 3 rank chest into a two rank

chest. New two rank configuration is now completed.

June 25, 2012

1) Completed cleaning the Robert Morton Oboe Horn rank. All pipes

have been wet cleaned, stripped and new lacquer applied to the zinc portions.

Larger pipes were cleaned by spraying "Scrubbing

Bubbles" cleaner on them and pressure washing them. All reeds and shallots

have been cleaned and resurfaced. All were full of coal dust

deposits.

April 13, 2012

1) Key contacts on all manuals adjusted for correct contact height,

including 2nd touch.

2) Changed progression of Solo swell shades sequence, so the volume change is

smoother. Exchanged bottom shades for top shades.

March 26, 2012

1) Lowered pressure on the English Post Horn from 18 1/2" to

17". Not much difference in pitch. Rank is more manageable now.

2) Chris Nordwall tuned all ranks in the Solo chamber.

March 25, 2012

1) Lubricated the front and back bearings on the blower motor.

2) repaired dead notes in Main Tibia and Diapason

3) Chris Nordwall tuned all ranks in the main chamber. Tonal finish was done to

the Tuba Horn and Diapason in the Main.

August 15, 2011

1) Fixed two dead notes in Main Tibia wind chest Low A# had particle

lodged in the primary valve. Low C# required primary valve adjustment.

2) Re-gasketed the bottom board on Main Tibia Clausa C side, and cleaned

the primary valve sealing surface.

July 08, 2011

1) Set pressure for the new Morton Solo Vox Humana. Was not able to

get 6" pressure due to incorrect springs. Will acquire low tension springs.

Set pressure to 8".

2) Tuned Solo Vox Humana and set tremulant speed. Sounds pretty good.

3) Touched up tuning on Kinura, Main Tibia and Diapason

July 05, 2011

1) Rank board holes for the Morton Solo Vox Humana was

re-drilled to accommodate the larger scale.

2) Installed Solo Vox rack board and Robert Morton pipes. Fits well into chest.

Many pipes are much taller. The new rank is from the Morton organ originally

installed in the Sequoia theater in Burlingame, California. Rank was originally

voiced on 6" wind pressure.

3) Prepared 6 more of the Main Tibia Clausa pipes for installation, stoppers

repacked and new leather on the lips.

March 22, 2011

1) Organ was tuned by Chris Nordwall for upcoming recording session

2) Completed reconfiguring "D" files on the Uniflex system for the

Main Diapason and included the 4' octave pipes in the rank, which were never

present before.

3) Regulation of the new main Diapason rank completed. Very nice.

4) Installed 11 rebuilt pneumatic motors on Chrysoglott action. Its sounds

pretty good now.

5) Final adjustment of the Solo Tibia tremulant completed

6) Installed some additional sound adsorption panels in both chambers, making

the overall sound a little tighter.

March 4, 2011

1) Made some adjustments to the rebuilt Wurlitzer Solo Tibia tremulant unit.

Required opening the gate valve to keep it from stalling. Between this repair

and previous repairs, the noise level of the instrument has been dramatically

reduced.

2) Reconfigured "D" files on the Uniflex system for the Main Diapason

and included the 4' octave pipes in the rank, which were never present before.

3) Did some rough tuning and regulation of the new main Diapason rank. It is

just what was needed. It is much louder and present than the original Wicks

rank. It sill requires the rest of the tuning collars installed, and final

regulation.

February 18, 2011

1) Completed installation of rebuilt Wurlitzer Solo Tibia tremulant unit. New

pallet valve and gasketing was done along with some cosmetic

improvements. No more squeaks when turning off and on. It runs well and is

quiet. The tremulant wind line is about 18" shorter then before.

February 11, 2011

1) Started rebuild on the Solo Wurlitzer Tibia tremulant unit. New

pallet valve and gasketing is required along with some cosmetic

improvements.

2) The new Main Diapason rank has new tuning collars attached so it can be tuned more easily.

February 2 & 4, 2011

1) Installed new Wurlitzer Tibia tremulant unit. This runs much

better that the OSI unit it replaces and is very noticeably much quieter than as

well. This one change reduces the overall mechanical noise of the instrument

when playing.

2) Started the replacement of the Wicks Diapason rank when the new one. The new

rank is larger scale and will provide a better foundation sound for the organ.

It will need tuning collars attached so it can be tuned more easily.

3) Started the replacement of the main Tibia rank wood pipes with a larger scale

Dennison rank. Some pipes will require repacking the stoppers.

January 20, 2011

1) Rebuilt a Wurlitzer tremulant unit to replace the noisy Main Tibia tremulant.

Pictures below depict the unit in pieces before assembly. All pneumatic motors

were recovered with new rubber cloth, new gate valve constructed to accommodate

the 2 1/2" PVC pipe, and most all pieces were striped and shellacked.

Maintenance log for Fall/Winter 2009 & year 2010

December 8, 2010

1) The entire organ was tuned by Chris Nordwall of Rose City organ

builders.

July 21, 2010

1) Bob Macneur installed and wired Reisner/OSI magnets in 8' Main trumpet offset

chest, replacing the external wired originals. Chest needs winding and

reassembly.

2) Mike Bryant reconfigured both the Main and Solo swell shades configuration.

All swell shades in the Solo now open, and only the Main shades that have no

linkages are dead. The original configuration in the definition file was totally

incorrect and did not have the swell shoe potentiometers range accounted for

correctly. This really opened up the sound of the organ.

July 12, 2010

1) Installed partially rebuilt pouch board in the C# side of the Oboe Horn

windchest. The pouch board required this as there were four partial ciphers. No

ciphers now. Also repaired wind leaks on the top board seal. The chest is now

almost leak free.

2) Finalized the wind line connection to the Oboe Horn chest. Resized one

segment so its is straight and secured fittings with sheet metal

screws.

3) Installed wind line supports for Oboe Horn and static wind to the

Xylophone/Glockenspiel winker.

4) Completed felt bushing for Oboe Horn rack board holes.

5) Applied felt strip to top of Solo Tibia tremulant unit so that it seals

better. The unit needs to be removed to repair wind leaks and fix squeak when

tremulant is shut off and on.

June 29, 2010

1) Chris Nordwall, with the assistance of Tom Sylar, tuned the entire organ,

including most pedal offsets. The organ sounds fantastic.

2) Wired Bass Drum and cymbal action to spreader. Repaired leaking primary valve

on tap cymbal and other wind leaks on traps counter. Replaced strap on Persian

Cymbal so that the Roll Cymbal works better.

3) Wind pressure on Chrysoglott and Traps now 15" with the addition of

another leaf spring. The Chrysoglott and traps sound much better, snappier.

June 28, 2010

1) Dennis Hedberg did total work on the Oboe Horn, Saxophone, Main Tuba Horn and

low 6 notes of the Moller French Trumpet. The Oboe Horn is now very useful as an

accompaniment stop. The Main Tuba Horn

is very even, nicely regulated.

2) Bob MacNeur winded the Kimball Bass drum and Cymbal action. Needs balance of

wiring and adjustment..

3) Found wind pressure on Chrysoglott and Traps now too low (11 1/2").

Needs another leaf spring added to winker.

June 25, 2010

1) Installed low 12 resonators of Solo Oboe Horn rank, ready for tuning.

2) The Chrysoglott is getting a minor rebuild by Bob MacNeur. The hammers will

be re-felted and blown pneumatic motors repaired.

3) Fixed non-functional stops on Accomp, Solo and Great divisions. Accomp 4'

Gambas, Great 16' Trumpet, Solo 8' English Post Horn.

4) The Kimball Bass drum and Cymbal action has been installed. Needs balance of

wiring and winding.

5) Fixed dead middle E in Main Diapason, incorrect assignment in ODF.

6) Jonas changed transpose buttons on console to combination level

up/down and load

7) Mike fixed key contact on middle D# on the Great manual. Required burnishing

shorting bar.

June 21, 2010

1) Installed 12 note offset chest for main 8' French Trumpet rank. Wiring and

winding still to be done.

2) Main Tuba/diapason regulator has been replaced and is working fine. Set

pressure 10 1/2" pressure.

3) Solo Oboe Horn rank has been installed and tuned down to tenor C. The wind

chest will require more work to removed ciphers and leaks.

4) The Chrysoglott is getting a minor rebuild by Bob MacNeur. The hammers will

be re-felted and blown pneumatic motors repaired.

5) Mike Bryant is working over the console, adjusting contact firing points on

the manuals and tightening loose stop tabs on the name board.

6) The Kimball Bass drum and Cymbal action has been rebuilt and is ready to

install.

May 11, 2010

1) Got the metal Glockenspiel hammers from the beadblaster and laquered them.

Ready to install.

2) Removed the leaking Main Tuba/diapason regulator for recovering.

Unfortunately, it was sealed to the wind trunk with Silicone gel. The Silicone

gel did not separate properly and destroyed the the bottom of the regulator and

damaged the top of the wind trunk. Will require a new bottom made and a repair

to the top of the wind trunk.

May 5, 2010

1) All dead notes in the Main Trumpet rank repaired. Rank has been tuned.

2) Replaced C# side pouch board from the Main Vox Humana chest after partial

re-leathering.

3) Installed repaired Tuba Horn resonators and tuned the pipes.

4) Finished the repair on the main Tuba Horn/Diapason tremulant unit.

Re-positioned weights on the Tuba regulator so the excursion is even when

tremulant is running. The regulator is badly in need of re-leathering. The

gussets are leaking. Temporarily fixed with Gorilla tape

5) Bob Macneur installed a loaner Wurlitzer Cymbal action in the Main

chamber. It is beautifully restored.

May 4, 2010

1) Repaired three dead notes in the Main Trumpet rank. Required dropping bottom

boards and pouch boards. Low C had defective magnet. Low D was ciphering because

of PVC particles in the primary. Low G was dead due to a blown pouch

pneumatic.

2) Removed C# side pouch board from the Main Vox Humana chest for partial

re-leathering.

3) Replaced defective magnet in English Horn low D#. Required dropping bottom

board to replace.

4) Picked up repaired Tuba Horn pipes from Mike deSarte.

May 3, 2010

1) Dennis Hedberg finished voicing the Gottfreid English Horn, and did

some work on the Saxophone. He removed brass sleeves and other restrictors that

were muffling the upper end. Much better.

2) Tuned all the major reeds plus the Saxophone, Kinura and Orchestral

Oboe

3) Mike Bryant and Bob MacNeu repaired dead notes in the Main chamber.

April 30, 2010

1) Installed more acoustical panels in the Main and Solo chambers. There is a

dramatic change in the overall sound because the excess ambience in the chambers

is damped out. The Solo Tibia tremulant is more more defined, and the overall

responsiveness of the attack of all ranks is much more defined.

2) Completed modification of the console pedal board attachment hardware. No

more lifting and cursing when connecting the pedal board. Just slide it into

position. The pedal board frame is on adjustable leveling pads so the height can

be adjusted very accurately. No more adjusting the magnetic reed switch

rail.

April 28, 2010

1) Started wind and wiring the Oboe Horn wind chest. About halfway thru each

task.

2) Moved some large sized acoustical panels into the Solo chamber to damp excess

ambience in the chamber.

April 21, 2010

1) Completed sizing the rack board holes for the Oboe Horn chest.

April 19, 2010

1) Completed re-leathering of the Solo C side Diapason pouch board, using

OSI manufactured pouches.

April 16, 2010

1) Placed the Oboe Horn wind chest on its chest bearers. Ready to install bottom

boards and wind lines

April 15, 2010

1) Started to assemble the chest bearers for the new Kimball Oboe Horn windchest.

April 2, 2010

1) Dennis Hedberg did some more tonal finishing on the Gottfried English Horn.

Several dead notes on the low octave need to be corrected. The low C# pipe

is missing.

2) The Devtronix computer locked up twice during the open console event

March 26, 2010

1) Removed pouch board from Solo C side Diapason chest to send to OSI for

analysis

2) Acquired large sound treatment panels to install in both chambers to dampen

excess reflections

3) Repaired two broken solder joints on resonators for the French Trumpet and

the low f# on the English Horn

March 24, 2010

1) Dennis Hedburg started tonal work on Gottfried English (post) Horn

rank. The wind pressure was raised to 18 1/2" W/C (water

column). The work is nearly complete and will take another session to

complete. But the difference is astonishing, its a completely new rank. One

small pipe is missing the reed tongue and shallot. The low C# pipe is missing

and apparently has been gone since the rank was installed in Benson high school.

The organ now has four very good chorus reed stops. (English Horn, Trumpet,

Harmonic Tuba, Tuba Horn)

2) Chased more dead notes in the main chamber. Some will require dropping bottom

boards to fix.

3) Started to process of acquiring replacement chest pouch pneumatics from Organ

Supply, inc (OSI).

March 23, 2010

1) Made back-up copy of the files in the Devtronix computer for

future use

2) Dennis Hedburg started tonal work on some reed ranks, including the Main Tuba

Horn and Trumpet and the Solo Harmonic Tuba and Saxophone.

The Saxophone is much better being more even and the

Solo Harmonic Tuba is very nice. The tonal work is called regulation and

consists of making the pipes equal in volume, timbre and the way they take

the tremulant consistent within the rank. The tenor

"G" in the tuba was too buzzy. When Dennis took it apart, he found a

dead insect carcass in the shallot. The note sounds much better without the

bug.

March 18, 2010

1) Finished bushing loose rack board holes on the new Trumpet

rank with adhesive backed felt from Grainger

2) Completed bushing loose Main Tibia racking with felt. They look much

straighter and will be more stable and easier to tune.

3) Started to rework the hammers on the Chrysoglott with softer felt. It will

sound much more delicate and Celesta like when completed.

4) The new chest bearers for the Oboe horn chest are complete. They were

finished shellacked by Bob Macneur.

5) Ordered and received the M66 blocks required to wire up the Oboe Horn chest.

Also have the insertion tool for the M66 blocks.

February 22, 2010

1) Work continues on the single rank Kimball chest for

the Oboe Horn. New rack board for C# side made, along with support pins, pipe

stays (reworked from Main Trumpet chest) and "hi-hats".

2) Started work on releathering the Bass Drum/Cymbal action. Pneumatics are full

of coal dust, very messy.

February 11, 2010

1) Installed most of the Wurlitzer Tuba Horn rank,

with the rebuilt pipe stays. Pressure is set to about 12" w/c. Rank boards

holes were enlarged using a router and purpose built templates. A few pipes are

still out for repair.

2) Replaced the not so good Morton Trumpet rank with an M. P. Moeller French

Trumpet. It really has the OK sound, being very much like a Wurlitzer

"brass" Trumpet. It is only from Tenor "c" for now until the

offset chest for the lowest 12 pipes is installed. It is the rank with the

flared bells, between the Flute Celeste and the Wurlitzer Orchestral Oboe.

February 6, 2010

1) Began work on the single rank wind chest that will

be for the Dennison Oboe rank in the Solo chamber. Rejoined to two halves into

one chest. The chest was rebuilt previously and will not require new leather.

November 25, 2009

1) Transferred cleaned Harmonic Tuba pipes to CHS main

chamber. It will require reaming the rack board holes to allow them to fit.

2) Installed new Wurlitzer winker for the Solo Glockenspiel and Xylophone,

removing these items from the pedal offset winding. They are now on their own

separate wind supply, set at 16" wind pressure

November 19, 2009

1) Cleared all dead notes from the Main Diapason rank

2) Installed new walk board between the back two windchests

3) Started looking into replacement of the too soft Main Wicks Diapason rank.

Have located a suitable replacement.

4) Damaged Tuba Horn and Orchestral Oboe pipes were sent off to Mike DeSarte for

repair.

Overview of Solo/Main Chamber Retrofit - Summer of 2009

Solo Chamber Project

One

of the chief complaints about the Cleveland High School organ has been the

"soft" and non-distinct sound of the Solo chamber. In this case,

"soft" does not pertain to the loudness of the chamber, it can get

plenty loud. The term "soft" refers to the lack of definition of the

ranks, and particularly the Tibia tremulant. This is caused by the size of the

chamber, which is almost double the volume required for the amount of ranks and

other effects installed in it.

The obvious solution would be to lower the ceiling

about 6-8 feet, but the logistics and cost of this would be prohibitive. This,

in conjunction with raising the windchests

would be the best solution. The best alternate option was to raise the

windchests at least 18". The rear, 3 rank chest was raised a total of 22

3/4" and the forward 4 rank, Kinura and Vox Humana chests were raised a

total of 18 3/4". This dramatically increased the ease of maintenance of

all the wind chests.

Four other things were done during the Solo chamber retrofit.

First, the sound killing walk board that ran over the center of the chests was

eliminated. It was extremely precarious to tune and work on pipes from it, plus

it blocked the sound of the treble pipes. Second, the Kinura chest was lowered so

that it didn't block the egress of the solo chamber pipes. Third,

the old walkboard was cut down to 16" wide and installed between the two

larger chests, so tuning and voicing pipes will be a lot easier. Finally,

12" square acoustical tiles and other types of acoustical treatment were attached to the walls of the chamber. The

tiles' purpose is to dampen excessive reverberation in the chamber. Although

this sounds counterintuitive, this is meant to increase the clarity of the sound

emanating from the chamber and to help define the Tibia tremulant.

Some changes in the winding scheme of the ranks was

done during the course of reconnecting windlines. The Tibia Clausa was

originally winded from the back of the chest with a 5" wind line. Since

5" PVC is not readily available, the wind line was changed to 4", and

was winded from the side of the chest. The interesting "Y"

configuration on the Solo tremulant was deleted. The OSI tremulant unit on

the Tibia Clausa was replaced by a Wurlitzer large scale tremulant, graciously

donated by a member.

Main Chamber Project

The

Main chamber suffers from the same installation errors as the Solo Chamber, but

there is more hardware packed into the same size chamber. The rear wind chest

that has the Main Tibia Clausa, Open Diapason and Harmonic Tuba was raised

24" and moved back 16". It required full reconfiguring of the

winding system, with new 4" PVC wind lines and relocating the tremulants.

The single rank Morton windchest that had the 4' Octave was deleted to make

room.

The sound killing walkboards that ran through the

center of the wind chests were also removed and a 15" wide walk board was

installed between the back two wind chests. This allows easy maintenance and

tuning of the Harmonic Tuba, Orchestral Oboe, and Trumpet ranks.

Almost all of the original windlines on the other two

main chests was also removed, including 40 pounds of 5" PVC line. The new

winding schemes are much simpler and less of a trip hazard. It is totally

amazing how much better things work when simplified. We keep on removing things

and the organ works and sounds better!

After measuring the wind pressure on the ranks

fed by Main I regulator, it was discovered that the pressure was too low

(< 10"). The pressure was raised to about 12" by adding two large

springs to the regulator, for a total of six springs. The sound of the Kimball

Violins and Concert Flute was dramatically improved. All the other wind

pressures were checked and adjusted as required.

The Main Vox Humana, a Wurlitzer rank, was louder than

the new Morton Solo Vox Humana. The rank was re-regulated by closing the tops

down so it is somewhat softer, blending better with the strings and

Tibia.

Blower Project

The blower has been a

potential Achilles Heal on this organ for years. The blower itself has been

installed in three or four different venues in its lifetime and soon will be on

its third motor (the current DC motor was not the original motor) . Since

July 24, 2009, the blower has not been functional because of a partially shorted

oil damped starter coil. The blower could be started but the coil would start to

smoke after about a minutes operation.

DC motor and blower issues:

1) The DC motor was rated at 1150 RPM at 230 VDC. It was running on at least 270

VDC and probably running faster than the 1150 RPM. Because of that, one of

the fans was removed to have to blower output less pressure, which has been

reported as 30" + static pressure. The higher RPM contributed to more

turbulence and wind noise. We were quoted $400-600 to install new motor brushes

and service the bearings.

2) The Cutler-Hammer DC motor starter dates from 1914, was obsoleted in 1933,

and the last spare parts were made in the 1960's. It has been modified over

time, the contacts are burned and is otherwise unreliable and unsafe. DC was

used when organ blowers were run off of city streetcar power. We were quoted

$600.00 to rewind the starter motor coil. There is no real way to tell what

other real or potential problems exist in the starter apparatus.

3) The fan that was removed had been installed at one time but was incorrectly

installed so that it scraped against the adjacent stator. There were numerous

aluminum particles found in the outlet butterfly valve. The rivets on the fan

were worn down and the edges were sufficiently scraped so the fan has to be

replaced, at an additional cost of $400.00.

The cost of repairing the DC motor and starter would be almost half of the cost of as new motor. And there still might have been hidden problems with the starter and motor. So, to ensure continued reliability, the decision was made to replace the DC motor with new 3 phase, 208 VAC, 20 HP motor. It will have three fans and will deliver sufficient static pressure to ensure no sagging wind pressure.

On October 6th, 2009, the new motor was

installed by Bob Otey of Seattle. The blower now has the original 3 stage

configuration and produces 23 1/2" static pressure at the blower. The

blower was balanced electronically and runs extremely smooth. The old blower

configuration imparted a low level rumble that could be heard throughout the

entire building. That noise is now completely gone and the organ makes no noise

when the swell shades are closed.

Maintenance log for Summer 2009

Below is a log of the daily events (starting

from the latest date):

Day 47 October 9, 2009

1) Moved console into auditorium for publicity photo

shoot

2) The entire organ is noticeably quieter in the auditorium. With the swell

shades closed, there is no noise heard from the organ. Before the blower motor

replacement and balancing, there was a noticeable low frequency rumble heard in

the auditorium.

3) Installed rack boards for the Main Diapason and Tibia Clausa and planted the

pipes.

4) With the direction of Dennis Hedberg, numerous adjustments were made in the

regulators and wind pressures.

5) Fixed leaks and ciphers on the Solo toy counter assembly.

6) There are still some minor leaks on the Main Tibia chest toe boards which

can't be fixed unless the chest is re-gasketed.

Day 46 October 8, 2009

1) The Tibia portion of the Main 3 rank chest continued to leak even after

shimming the screw holes with match sticks. It was decided to drill out the

holes and insert dowels.

2) Secured the bottom boards and the other two toe boards on the 3 rank chest.

3) Fixed numerous small wind leaks.

Day 45 October 7, 2009

1) Checked operation of blower in the chambers, some new

leaks to be addressed.

2) Started reassembly of the Main 3 rank chest after blowing out accumulated

dirt and dust. Even with vacuuming out the chests, there was still a lot of dirt

and dust inside.

Day 44 October 6, 2009

1) Installed new 20 Hp blower motor. All three stages

were electronically balanced and the blower runs very smoothly. Measured static

pressure at the blower is 23 1/2"

2) No apparent problems with the electrical service to the blower, no failures

after repeated starts and stops.

Day 43 September 24, 2009

1) Removed old DC motor from blower so new motor can

be installed next week. Required an engine hoist, floor jack and a pallet jack

borrowed from the high school.

2) Confirmed that existing motor starter is adequate for the new blower

motor.

Day 42 (August 31, 2009)

1) Completed the connection of the 4" windline

for the Main center windchest.

2) Installed metal cleats for the toy counter.

Day 41 (August 28, 2009)

1) Gary Hughes connected all the traps wiring in the Main chamber

and all the tremulant control wires.

2) Placed the rest of the Solo Violin Diapason, some pipes will need bushing on

the toes. Also, rolled out some dents in selected pipes.

3) Max did an extensive clean-up in the Solo chamber.

Day 40 (August 27, 2009)

1) Moved surplus pipes to storage

2) Milled some required parts for the Main 2 regulator windline connection and

Solo Xylophone/Glockenspiel winker

3) Planted the most of the new Gottfried (?) Violin Diapason in the Solo

chamber. Because the scale of the original Kimball Diaphonic Diapason was so

big, the new pipes were re-scaled in the manual chest, so the lowest pipe on the

manual chest is 8' GG. There 7 notes offset (CC thru FF#). Originally, the

Kimball Diapason started at tenor C on the manual chest and the lowest 12 notes

were offset.

4) Received the 1 rank Kimball for the Oboe Horn in the Solo chamber, stored in

blower room for now

Day 39 (August 26, 2009)

1) Cut and installed new 4" windline for the Main 2

regulator.

2) Installed 3" windline for the Solo chamber toy counter.

3) located the main breaker panel that feeds the breaker panel in the Main

chamber. It is located in the ante room in the Chemistry lab next door to the

main chamber. (panel C-1, 70 amp breaker, panel is rated at 225 amps.)

4) Prepared the Wurlitzer winker for installation on the Solo

xylophone/Glockenspiel instrument

Day 38 (August 25, 2009)

1) Max completed the installation of the Main 2' Tibia offset

chest by securing the cables and running a ground wire. Soldered the wires as

they were never soldered.

2) Started the winding of the Main 2 regulator to the middle 3 rank chest

3) Ran windline for the Main toy counter and secured signal cable

to the terminal board.

Day 37 (August 14, 2009)

1) Completed the new Vox Humana and Main I tremulant windlines

2) Marc Gerlack did a great job of preparing the side of the center Main cheat

for the refurbished side plate

3) Jerry Hertel prepared and glued new gaskets for the old side

plate

4) Max installed side plate and installed new wind lines

5) Mike Bryant prepared the 2' Tibia 12 note chest for installation

6) Installed above Tibia chest

Day 36 (August 13, 2009)

1) Completed Tuba/Diapason tremulant line, which required

modifying a support on the 16' Open Wood offset chest.

2) Secured the Main Tibia tremulant to the floor

3) Started to clean up the old Main and Vox Humana tremulant lines so they

aren't trip hazards and they are more straight forward in configuration. Not so

convoluted.

4) Discovered the most egregious, most amateurish and downright damaging

silicone gel job yet in the center three rank chest. This won't be corrected in

this round of retrofits.

5) Jonas donated a fully rebuilt Wurlitzer equalizer (winker). It will be used

to improve the winding of the Solo Xylophone and Glockenspiel.

Day 35 (August 12, 2009)

1) Completed all ground wire and buss connections to 3 rank chest

2) Moved 3" Bourdon windline to make way for the Tuba Tremulant line

3) Made an adjustment to the 4" Tuba windline and finished

connections.

4) Mike Bryant completed repair to the Tuba toe board and placed it on the wind

chest.

5) Ordered PVC pipe and fittings for Tuba tremulant windline

6) Started general clean up of the Main chamber

Day 34 (August 11, 2009)

1) Completed windlines for Main Tibia Clausa feed and tremulant

2) installed 4" adaptor and flange on Tuba/Diapason regulator.

3) Jonas and Marc completed the cutting and fitting the windline for the Main

Tuba/diapason chest

4) Finally found the circuit breaker for the blower motor. It was in the Main

chamber, not where we expected it to be.

Day 33 (August 10, 2009)

1) Started cutting wind lines for the Main Tibia Clausa and Tuba

chests

2) Jonas completed installation of the Solo Vox Humana

3) Check sent for initial payment for new AC blower motor.

4) secured and dressed wiring for the Main 3 rank chest

5) Installed bottom boards with two screws each to get them out of the way and

out of danger.

Day 32 (August 06, 2009)

1) No access to3rd floor due to floor waxing

2) Took measurements for Bob Otey to construct brackets for new blower

motor

3) Blower fans have been delivered to Bob Otey.

Day 31 (August 06, 2009)

1) No activity in the chambers due to floor cleaning and waxing

on the 3rd floor

2) Dismantled blower for preparation for the new 20 HP, 208 VAC, 3 phase motor

to be supplied by Bob Otey of Seattle. Found metal shavings on top of the outlet

butterfly valve due to incorrect installation of the

outer fan, which was scraping on the stator. Max noticed a

cracked weld on the bracket that held one of the motor brushes. Overall, the

decision to replace the DC motor with a new AC motor is a good

one, looking at all the inherent problems with the

DC motor.

Day 30 (August 05, 2009)

1) Max installed ground busses and wires for 3 rank chest

2) Installed new side panel for 3 rank chest

3) Mike finished the new gaskets for the Tuba toe board pouch rails.

4) Started preparation for the 4" windline connection on the Tuba regulator

Day 29 (August 04, 2009)

1) Secured another wiring terminal strip and began cleaning up

the cables

2) Mike completed the new gaskets on the Tibia toe board pouch rail, placed toe

board on chest.

3) Hauled off excess pipework and wind chest to storage.

4) Acquired a Robert Morton 10" scale Vox Humana for the Solo Chamber.

Jonas and Marc Gerlach installed it.

5) Mike and Max started preparing the Tuba toe board for new gaskets on the

pouch rails

6) Jonas and Marc started to disassemble the blower for conversion to a new AC

motor.

Day 28 (August 03, 2009)

1) Assembled new chest bearers for 3 rank chest in hallway

2) Moved and reassembled chest frame and bearers in the Main chamber

3) Secured new chest bearers to the floor with 1" plywood pads using

1/4" lag bolts

4) installed one Tibia bottom board and secured cable terminal strip

5) Mike inspected the toe boards for the Tibia and Diapason, will require new

paper gaskets on the Tibia pouch rails. Pouch leather looks OK.

6) Jonas inquired about additional options for the blower. It may cost thousands

to repair.

Day 27 (July 31, 2009)

1) Removed and prepared the Main back 3 rank windchest frame for

installation. It required lots of filling putty, sanding and bushing screw holes

and other repairs.

2) Cleaned out and removed almost all of the hardware in the hallway.

Access to the organ chambers will be limited next week when the CHS

custodians wax the floor.

3) Gary Hughes brought in a capacitive/inductive tester and determined that the

blower starting coil is partially shorted. We will find a licensed shop that can

rewind the coil.

4) Received some documentation on the blower motor

starter unit from Cutler-Hammer, which was obsoleted in 1933.

Day 26 (July 30, 2009)

Work was canceled yesterday due to the extremely hot

weather.

1) Ran ground wire for the 12 note Tibia 2' chest

2) Connected the Solo and Solo Brass tremulant control wires

3) Cleaned the Solo chamber and removed all the accumulated tools and supplies

4) Started to clean the hallway of all accumulated parts and lumber

4) Had an electrician look at the blower motor starter device to explore options

to repair or upgrade

Day 25 (July 27, 2009)

1) Still looking at options for the blower starter

2) Fixed a crack in a Solo Tibia bottom board

3) Started winding the traps in the Main chamber

4) Continued with the dismantling of the Main rear 3 rank chest. Found more

Silicone gel troubles but found an adaptor on a 12 note treble chest that

actually had a leather gasket on it!

Day 24 (July 24, 2009)

1) Fixed some leaks on the Solo manifold

2) Fixed a cipher in the Solo Tibia, which required dropping the bottom board,

yet another glob of silicone gel. See picture below.

3) Fixed a dead note in the Solo Tibia which required removing the Tibia pipes

and the toe board. The dead note was caused by a port not opened when the new

gasket material was glued in. The new gasket material was required because of

the silicone gel used to fix leaks. See #item 2 and entry from day 2.

4) The DC starter device on the blower motor failed. The organ is non functional

until this is fixed. Various options are being explored. It is not known how

long this will take or how much it will cost.

![]()

Day 23 (July 23, 2009)

1) Max finished installing the new screws into the Kinura

chest bottom board. No leaks! Replaced the old 3" #12 straight slot flat

head screws with Philips head screws, along with new washers..

2) Planted the Kinura pipes

3) Jonas experimented more with the Solo Tibia tremulant, shortened the windline

about 4-5'

4) Did some re-winding in the Main chamber to allow the blower to be turned on

again. The new winding when installed will be much simpler and

cleaner.

5) Removed the center walkboard from the Main chamber

6) Had a large crew today, so we were able to hoist the Main traps assembly into

place on top of the Harp. It fits like its supposed to. Its ready to wind and

wire.

Day 22 (July 22, 2009)

1) Finished winding the Kinura chest

2) Fixed wind leak on Solo manifold

3) Checked and set wind pressures in Solo chamber. Set as follows:

a) Solo - 10 1/2"

b) Solo Brass - 11"

c) Tibia Clausa - 13 1/2"

d) Vox Humana - 6"

4) Secured terminal board for the Solo 4 rank chest

5) Started work on raising at least one of the Main windchests by removing the

Main Tibia and Diapason ranks and removing the toe boards on the 3 rank

chest.

Day 21 (July 21, 2009)

1) Wheeled out the console and heard the results of the

work. The sound is much improved, even though everything is very out of tune.

2) Cleared a cipher from the Solo Tuba that required dropping a bottom board.

Yet another glob of silicone gel lodged in the primary valve.

3) Discovered a dead note in the Solo Tibia (middle A) probably a blown pouch.

4) The Morton Diapason transplanted form the main chamber is still too tubby for

the desired sound.

Day 20 (July 20, 2009)

- one small step for a man.................

1) Fastened the 2' Tibia rack board and planted the pipes

2) Installed Kinura chest with new chest bearers. Routed the Solo tremulant line

through the chest bearer to save space.

3) Completed tying the pipe stays for the English Horn

4) Confirmed measurements for the Main chamber move

5) A subjective measurement of the Solo vs. the Main reverb times indicates the

Solo is now tighter than the main.

Day 19 (July 17, 2009)

1) Finished installing Diapason pipes including 4' Octave

2) Planted the 4' Clarion pipes

3) Max cut and glued the gaskets for the 2' Tibia extension wind chest

4) Mounted the 2' Tibia extension wind chest, Max secured the wiring for

it.

5) Fixed cipher in Diapason chest, required dropping the bottom board

6) Planted the Tibia Clausa pipes on the wind chest, with the help of Bob

Macneur

7) Mounted the acoustical tile donated by Jerry Hertel. The room is definitely

getting tighter, less reverberant.

Day 18 (July 16, 2009)

1) Installed the rest of the English Horn, Diapason

and Harmonic Tuba ranks using brand new cotton twill tape on the pipe stays.

Discovered that the Harmonic Tuba is harmonic from Tenor C on up.

2) Installed the Trivo Saxophone

3) Jonas has made some preliminary adjustments on the tremulants

Day 17 (July 15, 2009)

1) Installed Gamba, Gamba Celeste ranks.

2) Started to install English Horn, Diapason and Harmonic Tuba ranks. Discovered

that the tenor D and D# boots on the Harmonic Tuba had been swapped when last

installed.

3) Repaired one blown pneumatic pouch on the C side of the Diapason, another one

was to far gone top repair.

4) Fixed ciphers on the Tuba chest, found screws holes drilled horizontally into

the to boards were leaking. Plugged holes. Probably the same solution on the

Post horn chest.

5) Made new rear plate for the 12 note Tibia 2' extension chest

Day 16 (July 14, 2009)

1) Installed braces for Tibia Clausa tremulant.

2) Installed new 5" PVC wind line extension for the Solo ranks

3) Chased more wind leaks and ciphers on the Solo windchest. Required dropping

one bottom board.

4) Drilled 1 1/2" hole for the 2' Tibia 12 note extension windchest. Cannot

install the chest as the back plate has to be reworked. Plugged hole.

Day 15 (July 13, 2009)

1) Repaired pneumatic motor on the large Wurlitzer tremulant

unit and assembled the tremulant.

2) Installed new Tibia Clausa tremulant wind line. It really

shakes that regualtor! It will have to have a gate valve to scale back the

tremulant a bit.

3) Chased more wind leaks and ciphers

4) Installed braces for Solo Brass tremulant wind line

Day 14 (July 10, 2009)

1) Installed new ladder for accessing the walkboard in

front of the Tibia Clausa offset

2) Secured Solo tremulant to the floor and 4" wind line going to the Piano

and traps.

3) Spent the rest of the day chasing ciphers and dead notes.

4) Ordered more 2 1/2" pipe for the Tibia Tremulant wind line

Day 13 (July 9, 2009)

1) Installed new wind line for the Solo Brass

tremulant. (see picture below)

2) Installed new wind line for the Solo tremulant

3) Paul Quarino donated a large size Wurlitzer Tremulant for the Solo Tibia

Clausa. It will require a very minor rebuild before installing, Many thanks to

Paul.

4) Mike Bryant and Rob Kingdom decide to relocate the Kinura windchest so that

it will be directly in front of the Vox Humana wind chest. This will be the

closest rank to the swell shades for maximum egress.

5) Jack Powers finished the ground wires for all the chests.

Day 12 (July 8, 2009)

1) Installed 2 1/2" Vox Humana tremulant wind

line.

2) Started fixing leaks and ciphers. Lots of debris in the chests including a

small clump of Silicone gel lodged in a primary valve. This required dropping 3

bottom boards to address these issues.

3) The primary pneumatics we saw were in very good condition, they should be

reliable for years to come.

Day 11 (July 7, 2009)

1) Max installed the corner brackets on Vox Humana chest, trimmed the walk board

support so the new Tibia wind line would clear

2) Connected the separate 4" wind supply wind lines to the Tibia Clausa and

Tuba/Diapason.

3) Secured the wiring terminal for the Vox Humana chest.

4) Connected the new wind lines for the English (post) Horn.

5) Max and Steve Jarvis installed the Vox Humana bottom board and ensured that

all the screws secured correctly.

6) The one "Wurlitzer" tremulant unit we have turns out to be

Robert Morton. Probably will install it where it was before but with cleaned up

wind lines. Anybody out there that would like to donate a large Wurlitzer

tremulant?

7) Turned on the blower a couple of different times to blow out the chests.

Quite a few ciphers left over from before the move. Plugged a few leaking screw

holes. No apparent leaks in the new winding.

Day 10 (July 6, 2009)

1) Max installed all the required flanges for the

various wind lines (not "air pipes")

2) Connected the wind supply to the Vox Humana wind chest and placed the chest.

3) Secured the wiring terminal for the 4 rank chest.

4) Jack finished replacing the missing magnet on the Vox Humana chest and

checked all the remaining magnets.

5) Jonas Nordwall inspected the work and was duly impressed. He suggested that

we move the one Wurlitzer tremulant unit we have to the Tibia instead of

the Solo. The Solo and Solo brass trems will be OSI.

6) Acquired the required fittings, pipe and screws for tomorrows' work.

Day 9 (July 2, 2009)

1) Max finished installing the 4 rank chest bottom

board screws.

2) Jack and Jerry finished the ground wires and busses for both chests.

3) All toe boards and rack boards were cleaned and rack boards were installed

4) Finished and attached the chest bearers, and replaced a missing (hole

was stuffed with a napkin) magnet for the Vox Humana chest.

5) Rudy started the massive task of cleaning and vacuuming the chamber floor.

Day 8 (July 1, 2009)

1) All bottom boards installed onto

the 4 rank chest, after replacing dead magnets and cleaning the bottom boards.

2) Installed bracing for the Tibia offset walk board.

3) Mike prepared the chest bearers for the Vox Humana chest. Again, a five

minute job turns into 2 hours due to silicone gel sealant from the

previous use.

4) Turned the sound destroying center walk board into a new walk board in

between chests

Day 7 (June 30, 2009)

1) All toe boards installed onto

the 4 rank chest, after repairing gaskets and filling unused screw holes.

2) All bottom boards installed on the 3 rank chest, along with exchanged magnets

replacing the two dead ones.

3) Installed the two blank off plates on the Tibia chest

4) Started to install the Tibia winding

Day 6 (June 29, 2009)

1) The Solo 4 rank chest is up on its new legs and secured to the

floor

2) Installed the braces for the center walk board

3) Repaired a few toe board gaskets for the 4 rank chest

4) Jack replaced some dead magnets on the Tibia chest

Day 4 (June 25, 2009)

We accomplished a lot today, and we had a large, enthusiastic

crew on hand as well.

1) Clayton and Rick rearranged the Tibia regulator springs to ease the new

winding

2) Rick and Rob got the new chest bearers level and attached to the floor

3) Aaron punched out the the holes in the toe board gaskets

4) Mike and others got the new toe board gaskets glued into place

5) Mike and others mounted the toe boards

6) Rick and Rob made new supports for the Tibia offset chest walk board

7) Rick, Aaron and Clayton removed the Kinura and Vox humana wind chests

8) All the rest of the pipes from the manual chests were removed and

stored

9) Jeanette and Luurt cleaned and vacuumed both chambers.

10) Luurt, Aaron and Charles started attaching acoustical tiles to the chamber

walls

Day 2 (June 23, 2009)

1) Removed toeboards from the 3 rank chest, only to discover that Silicone

gel had been used to seal leaks. The Silicone had partially to almost completely

blocked the air flow from the primaries to the toeboards. No wonder the ranks on

this chest had inconsistent attack. This is why amateurs and hobbyists should

refrain from attempting repairs on pipe organs, without consulting someone who

knows how to do it. This will require stripping off the old gaskets and

Silicone goo and replacing it with new packing leather gaskets.

Day 1 (June 22, 2009)

1)Removed the French Horn chest with its chest bearers, Solo II and Tibia

tremulants

2) Removed and stored the pipework from the 3 rank chest. Discovered that none

of the chests were cleated to the floor, just free standing.

Main II Regulator rebuild - 2007

16

Blown out gussets and rotten leather

New wooden parts on left ready to use

Underside of completed regulator. The bottom plate is all new as the old one had too many unused holes sealed with silicone gel to be really viable.

Completed Regulator, ready to install. Of the three top plates, the nearest two were made new as the condition of the old wood was not good.

In the course of this task, we learned that both the Marimba/Harp and the Chrysoglott have primary, secondary, and tertiary pneumatics! Three pneumatics per note. Many of the traps action have the same configuration as well, which makes them very fast and responsive.

Also during the course of this re-winding job, every effort was made to recycle materials. No new PVC pipe was purchased, only a few fittings. The wood used for the replica winker was surplus from previous projects and the wood for the Marimba/harp manifold was recycled from 90 year old theatre pipe organs. A very "Green" project!

Winkers before final finish and covering - the replica is the top one. All materials are recycled.

The rebuilt Wurlitzer "Winker" (upper left) in its new home, supplying air to the Harp at about 14" pressure. The lower right is a replica built by Rob Kingdom, supplying the Chrysoglott and traps at 13.5" pressure. The inlet to the winkers are mounted directly to the wind trunk.

Pre-fitting the new Chrysoglott winker onto the wind trunk. Mounting the inlet directly to the wind trunk saves space and a couple of flanges and fittings. Notice that the technicians fingers never leave his hands.

The pneumatic motor has been recovered and the wood pieces are re-finished. Notice even the metal hinges and springs have been cleaned and polished.

Completed Persian Cymbal Unit

The Persian Cymbal has a large motor for a Gong effect and two smaller motors for the Persian cymbal roll.

-

Both the Marimba Harp and Chrysoglott have now been rewinded and the difference in performance is striking (no pun intended). Although we have not had a chance to play them from the console yet, testing in the chamber demonstrates that you can now play repeating chords and all the notes will play. Volume and response seem to be orders of magnitude better. Weíll have a little regulation to do once we hook the console back up. Rob Kingdom, Jack Powers (picture on upper left below), Jerry Hertel and Mike Bryant (The "winding wizard" pictured lower right below) finished the installation of the winkers and associated rewinding last Friday (07/23). The new "winkers" are shown in picture on upper right below.

-

Mike finished releathering the four blown Chrysoglott pneumatics, and Rob reinstalled them. All notes now play. The Harp has one dead note that needs troubleshooting and correcting.

-

All of the traps and toy counters have been removed from the Main chamber and taken off site for repair and rebuilding. Jack Powers and Bob MacNeur assisted Rob in the removal. Mike has begun work on some pieces, and Rob has the remainder. Current plans call for some of the traps to be moved to the Solo chamber, where they can be mounted on a wall close to the shutters. This will enable them to be heard much better than the old layout. Refurbishment of the Sleigh Bells actions, Bird Whistle and Acme siren are in progress as of this date. We can look forward to stereo Bird Whistles, one in each chamber.

-

Some of the traps show signs of having been rebuilt in the past. While much of the work appears to have been quite well done, once installation began things went downhill. Silicone sealant or something like it (also known as ďorgan builder in a tubeĒ) was used instead of the correct gasket or sealing material. This will all need to be cleaned off, and the wooden pieces refinished. Getting the sealant off without ruining the piece is a tough job and this turns a five minute job into a five day job. There will be opportunities for those who are so inclined to visit Mikeís house and help with the preparation and refurbishment. Contact Mike directly (mbryant3@earthlink.net or (206) 619-6645). By the way, the sealant gel shouldn't be confused with the Butyl o-rings used to seal the wind lines. The o-rings work out quite well and save a lot of time.

-

Donations to help pay for the materials (mostly leather) needed for the traps refurbishment will be gratefully accepted. Talk to Rob Kingdom or Rob Vastine if you want to help out, or can talk a friend into helping out.

-

Several of the traps were not usable simply because no control for them existed on the console. Mike is working to come up with a solution so that all devices can be used when they are reinstalled.

-

The Main Harmonic Tuba pressure has been raised to 15" from about 11". This should make the Tuba a little more assertive. Of course, it will require retuning. The 16' octave extension of this rank, the 16' Bombarde, still has problems. We believe it is a Robert Morton set with wooden resonators and should be speaking on 15" of pressure. It currently is on 10" and most notes just don't want to speak, sometimes at all. A separate regulator has been acquired and will be rebuilt and installed.

-

Many major and some minor wind leaks have been fixed in the Main chamber. The noise in the Main chamber was much louder than the Solo chamber. It now seems as the Main is quieter the the Solo!

-

The Main Tibia Clausa tremulant unit has been exchanged for a little larger one and installed in a different location (see picture lower left below). You may have noticed in the past that there was a huge difference in volume and tremulant operation between the Tibias in the Main and Solo chambers. This was caused by the pressure for the main Tibia being way too low, and the tremulant was the wrong size (it was a size appropriate for a Vox Humana, which doesnít need to move nearly as much air through). We have installed heavier springs to bring the pressure up to where it should be, and Jonas Nordwall has provided us a mo' betta tremulant unit in exchange for the small one. Preliminary audition of the new tremulant sounds just great, it really wails! And after replacing a dead magnet, there are no dead notes in the Main Tibia!

-

Main Tibia Clausa pipes have had all the stoppers repacked and rough tuned. With these stoppers corrected and the rank re-regulated, the rank should just sing.

-

08/13/08 - Clayton and Rick Parks (Elsinore Theatre) stopped by Wednesday 8/13/08 to donate a Kimball Winker and dice box for future use. While they were here, they assisted with tuning the metal Diaphones in the Solo Chamber. Many of the pipes were way sharp and one had some trouble with slow speech. With the expertise of Clayton and Rick, all notes play, are in tune and speak properly. Many, Many thanks to Clayton and Rick.

-

08/25/08 Mike Bryant has refurbished the Sleigh bells and Surf/Aeroplane actions and they look just like or even maybe better than new. See pix above.

Fall 2008 Log Entries

09/03/08 - Because we were able to play the instrument from the console yesterday, we made the following observations:

Positive:

-

The main Tibia Clausa with the new tremulant is fabulous. What a sound!

-

The Marimba/Harp is plenty loud and now very useful

-

The Chrysoglott is much improved

-

The Main chamber noise is significantly lower and is less than the Solo

-

With the III rank Mixture stop and wind chest removed, the Main chamber sound seems much more present. The Mixture was blocking some egress of the sound. The Mixture has been removed for long term refurbishing and relocation. (very, very long term refurb and relocation will probably be somewhere in the Portland metro area)

Less than optimum:

-

The Main Tibia Clausa needs some regulation work to knock the rough edges off.

-

The way the wind chests are installed with the walk boards over the chest, serious tuning and regulation work on the some of the reeds is shear Chinese water torture. Some rackbaord holes for the Orchestral Oboe are too small and the pipes don't seat correctly on the chest. Correcting this will be painful because of the location.

-

The Chrysoglott has one blown pneumatic motor and both the harp and Chrys need regulation work

-

The Main trumpet is a piece of ca-ca and needs a lot of work.

-

Many rackboard holes for the whistles (upper work) are way oversize. This results in making it extremely difficult to tune if the pitch has to be lowered. You are trying to tap the collar up, and instead of moving, the pipe just lifts up out of the hole. Because the pipe sits (in some cases) directly under the walk board, you really canít hold on to the pipe and tune it at the same time. So the technique is to pull the pipe, pull the collar way flat, then try to locate the hole in the chest by feel, and then tune it. These holes need to be reamed out to a size where they can be lined with felt that will grip the pipe.

-

If the Chrysoglott continues to show up blown power pneumatics, it should probably be rebuilt completely. If that leather is going bad, the internal leather canít be too far behind. And a rebuild is not something that can really be done in place.

-

The harp does need quite a bit of regulation. At present itís pretty clunky. It appears that attempts were made (unsuccessfully) to regulate it into playing correctly when the real problem was winding. So we need to undo that, and it should sound great. Thatís an easy fix.

-

09/06/08 - Observations from the First Friday event: The organ sounds much better overall. The Main Harmonic Tuba tuning is not stable and will probably have to lower the pressure to about 12" to improve it.

09/21/08 - Mike Bryant has completed refurbishing the Chinese Gong/ Persian Cymbal action. See pictures above. Work continues on the Marr & Colton regulator for the 16' Robert-Morton Bombarde offset chest. Word from John Ledwon through Rick Parks is that the Bombarde should be on 15" wind pressure and if it is a later set, it should be on 20".

10/23/08 - We finally got a measurement of the static wind pressure, 18". Lower than expected but still adequate. With the help of Jonas Nordwall, we started to re-voice the Solo Tibia. While attempting to set the operation of the regulator valves, we found the homemade copy of a Wurlitzer regulator was not operating correctly. Acquisition of a new valve plate and top board is in progress. Mike Bryant repaired the none functional stop tabs in the console that didn't work due to broken solder joints. He also tightened more of the loose stop tabs.

11/06/08 The valve plate for the Solo Tibia Regulator has been rebuilt using Wurlitzer valves instead of the homemade ones. Jonas Nordwall set the valves and the regulator now works as it should. The tremulant now sounds like a Wurlitzer trem should. See pictures below.

11/07/08 Jonas Nordwall set the Solo Tibia regulator valves and re-regulated the Solo Tibia. The improvement of the sound is very noticeable. The pressure was reduced from 14" to 13" and the trebles were opened up to clean up the sound. The Main Tibia pressure was raised to about 12" and re-tuned. It sounds absolutely fabulous. It was determined that the walkboard over the rear chest was blocking some of the sound so we removed it. What a difference!

11/17/08 Only a few of the lower Solo chamber swell shades were opening. Inspection showed that almost all of the pneumatic motors had small holes and some primaries were not working. Mike Bryant and Rob Kingdom removed the 14 motors for recovering. The old material was rubber cloth that was very stiff and dried out, and the overlaps were 2 1/2 " wide. This wide overlap made the motors even less flexible.

11/18/08 Pictured below are the 14 recovered swell shade motors from the lower solo swell shades, ready for installation. 14 down, 42 to go.

11/24/08 The 14 rebuilt Solo swell shade motors have been installed and two primaries were replaced as well. With the help of Bob Macneur, all the lower Solo swell shades now operate and are quiet when opening and closing.

11/.28/08 The Main Bombarde regulator has been installed but needs some fine tuning as it wants to oscillate with no load. The Bombarde does seem to speak better on higher (15") pressure.

05/01/2009 The wind trunk for the Solo traps and percussions was hoisted into place. Now for winding and wiring! Picture below shows traps units ready for delivery to CHS.

-

Click here to read and see 3/25 History 3/25 Console 3/25 Specs 3/25 Events 3/25 Refurb and Maintenance