COLOUR REVERSAL FILMS FOR BEGINNERS

By David Morrell (Area 4)

Most colour slide films on the market today are compatible with the Kodak E-6 process. The exceptions to this are Kodak`s own Kodachrome, which is a non-substantive film, and possibly some of the eastern European cheepo`s, which still use the old Agfa formulae. The latest Agfa films are E-6 compatible.

COLOUR FILM COMPOSITION:

Colour film, both negative and reversal, consists of several layers of emulsion on a strong plastic base. They are positioned as follows: Blue Sensitive Emulsion. Yellow Filter. Green Sensitive Emulsion. Red Sensitive Emulsion. Film Base.

As all three layers of emulsion are sensitive to blue light to a greater or lesser degree, a yellow filter is placed between the blue and green sensitive layers. This blocks the blue light but allows red and green light to pass through.

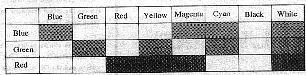

Colours are registered as in the following diagram:

Before going into the actual process, a word of warning.

Many of the chemicals used in colour processing are highly toxic. Some are powerful irritants to the skin, the eyes, the nose and the

respiratory organs. In extreme cases contact with or inhalation of these chemicals can cause severe illness. The safest thing to do is to wear

rubber gloves. Having said that it is worth bearing in mind that no chemical is dangerous, only the user.

FIRST DEVELOPMENT (Alkaline):

This uses a black and white developer, of similar strength and contrast to print developer, to produce a black and white negative silver image in each layer of the emulsion. The composition of the developer, the time and the temperature are all critical factors in producing first class results. Unless we are prepared for a bit of chemistry we can control only two of these, the time and the temperature. A stop clock and certified

thermometer are well worth the money.

STOP BATH OR WASH (Acid Or Neutral):

This stage depends on the processing outfit in use. If the kit comes with a Chemical reversal stage this will be a wash for about two to three minutes. If light reversal is being used then this will be a stop bath for about two minutes. All it is for is to neutralise the effect of the first

developer.

WASH OR CHEMICAL REVERSAL BATH (Neutral Or Acid):

This stage depends on the previous stage. If it is a wash it is to get rid of all traces of the stop bath to prevent contamination of the colour developer. If it is a reversal bath its purpose is to fog all the remaining undeveloped emulsion on the film. At one time I preferred light

reversal for reasons of economy and safety, chemical reversal chemicals can be particularly noxious. These days I do use chemical reversal

because most of the E-6 films do not give their best with light reversal. This is not to say it wont work, it does.

REVERSAL EXPOSURE (If not using Chemical Reversal):

This has the same effect on the film as chemical reversal.COLOUR DEVELOPMENT (Alkaline):

As for the first developer time and temperature are important but not as much so. During this development the rest of the silver halides left

on the film by the first developer and fogged during the reversal process are changed into a black and white positive image. The reversal

stage uses the black and white negative image from the first development as a negative to expose for this stage. At the same time as this

black and white positive is being formed, colour couplers in the emulsion are combining with chemicals in the developer to produce a positive coloured dye image. The depth and proportion of these colours is dependant upon the amount of silver halides left on the film at the end of

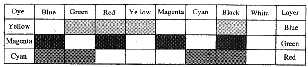

the first development. If too little is available the slide will be too light and lacking in colour. If too much is available the slide will be very dense and dark. The dye image is produced as in the following diagram:-

The blue sensitive layer produces a yellow dye, the green sensitive layer produces a magenta dye and the red sensitive layer produces a

cyan dye.

STOP BATH (Acid Or Wash):

This kit uses a 1 minute washCONDITIONER:

Surprisingly enough this conditions the film ready for bleaching.

This is only needed with the more recent Ferric E.D.T.A. bleaches. The older Ferricyanide bleaches were much more potent.

BLEACH (Acid):

This bath converts the black and white silver images on the film into silver bromide which can be dissolved by the fixer. Time and temperature

are not as critical for this stage as bleaching has to be taken to finality. At the end of this stage the film is usually cyan coloured on the

backing side (shiny side) and an orangey-brown on the emulsion side. If taken from the reel and held up to the light colours can be seen

but they are not very accurate.

RINSE:

This is not strictly necessary but does prevent the fixer from becoming yellow.

FIXER (Acid):

The last chemical step is to convert the silver bromide into a water soluble compound. Some of this dissolves in the fixer the rest, comes out in the final wash. At this stage the film has a milky appearance and the true colours cannot be fully distinguished until it dries. Any bad colour cast can be seen at this stage.

FINAL WASH:

This wash must be thorough. It removes all the rest of the soluble silver thio-sulphate compounds from the emulsion. If any of these are left in the emulsion then the film will suffer from bad staining and deterioration of the colours.

STABILISER:

The stabiliser has three effects on the film, none of which are immediately apparent. It helps to prevent the dyes from fading due to the action of light. (This is one area where Kodachrome, because of its particular make-up scores heavily over most other colour slide films.) It hardens the emulsion against physical damage. It helps the film to dry evenly. There are one or two kits on the market which do not provide a stabiliser. They say they are not necessary with modern emulsions. If you still would like to use one a simple one can be made up from the following formula:-

10mls 40% Formaldehyde. 5mls Wetting agent. 1Ltr Water.

CAUTION:

Formaldehyde is a skin and eye irritant and even the vapour can cause sore eyes so always mix and use the stabiliser in a well ventilated room.

The film must now be hung up to dry.

The following is the time and temperature schedule for the club Kit.1. First development 7 - 7½ mins 38+/-0.25C 2. Wash 3 mins 35 - 40C 3. Reversal bath 2 mins 37 - 39C 4. Brief rinse 5. Colour development 6 mins 37.50- 38.5C 6. Wash 1 mins 37 - 39C 7. Conditioner 2 mins 35 - 40C 8. Brief rinse 9. Bleach 7 mins 37 - 39C Invert twice every 30secs. 10. Brief rinse 11. Fix 4 mins 37 - 39C 12. Wash 6 mins 35 - 40C 13. Stabilise 1 min 37 - 39C 14. Dry Below 50C